Offshore Turbine Inspection | AI-Driven Drone & Infrared Analysis by Blade³.ai

Smarter Offshore Inspections. Faster, Safer, Predictive.

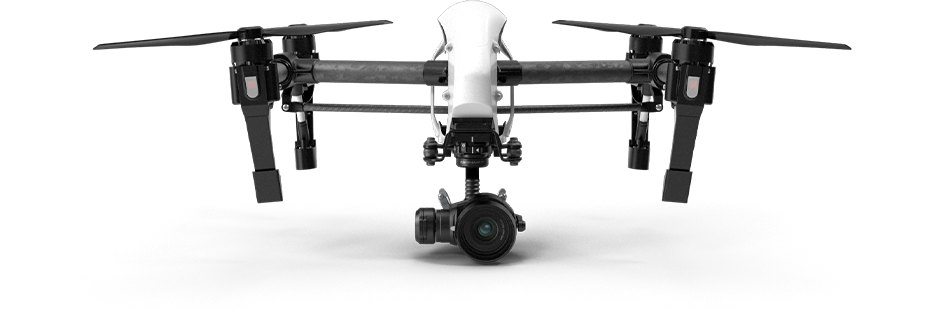

Blade³.ai redefines offshore turbine inspection with intelligent drones, AI defect detection, and infrared thermal imaging.

By eliminating manual climbs and lengthy vessel operations, Blade³.ai enables faster, safer, and more consistent offshore inspections — providing real-time, data-driven insights even in the harshest marine conditions.

What Is Offshore Turbine Inspection?

Offshore turbine inspection is the process of evaluating turbine blades, towers, and nacelles in marine environments to detect cracks, corrosion, erosion, or thermal stress.

Traditional methods require crewed vessels, rope access, and stable weather windows — often leading to delays and high operational costs.

Blade³.ai replaces that process with autonomous drones and AI analytics, delivering full visual and thermal assessments in hours instead of days.

⸻

Why Choose Blade³.ai for Offshore Wind

• Marine-Grade Autonomy — Optimized flight paths for ocean winds, glare, and turbulence.

• Infrared + RGB Fusion — Dual-sensor imaging reveals both visible and thermal defects.

• AI Damage Classification — Automatically identifies cracks, lightning strikes, and coating wear.

• Predictive Maintenance — Forecasts blade and component degradation before it becomes critical.

• Minimal Vessel Time — Reduces crewed missions and vessel charters.

• Instant Cloud Reporting — Access, share, and act on data in real time from any device.

⸻

How Blade³.ai Offshore Inspection Works

1. Autonomous Flight Planning

AI designs safe, optimized drone routes around offshore turbines considering wind, sea motion, and geometry.

2. High-Resolution Capture

4K RGB and infrared cameras record turbine surfaces and heat distribution from root to tip.

3. AI Analysis

Deep learning models identify defects, rank severity, and pinpoint exact locations.

4. Thermal Mapping

Infrared data highlights friction points, hotspots, and internal fatigue zones.

5. 3D Digital Twin Creation

Inspection data is converted into an interactive 3D model for long-term tracking and reporting.

⸻

Challenges Solved by Blade³.ai

• Weather & Sea State: Stabilized imaging and AI correction handle turbulence and motion blur.

• Safety: Eliminates rope access and minimizes time at sea.

• Speed: Reduces inspection cycles from days to hours.

• Data Quality: Delivers consistent, repeatable data across sites and timeframes.

⸻

Applications

• Routine offshore O&M inspections

• Post-storm or lightning damage assessment

• End-of-warranty documentation

• Blade life-extension analysis

• Commissioning and baseline reporting

Schedule a Demo

See how Blade³.ai Offshore Inspection brings AI-powered precision to offshore turbine monitoring.

Experience real-time detection, thermal overlays, and predictive analytics designed for the world’s toughest environments.

Benefits of 3D Turbine Modeling & Digital Twins

Blade³.ai’s 3D turbine modeling technology transforms inspection data into high-fidelity digital twins, giving operators a live, intelligent view of turbine health, performance, and structural integrity across their entire fleet.

| Benefit | Description | Impact |

|---|---|---|

| Full 3D Visibility | Digital twins allow complete visualization of each turbine, blade, and surface, providing precise detail for damage measurement and monitoring. | Comprehensive situational awareness |

| AI-Driven Accuracy | Blade³.ai’s AI reconstruction ensures sub-millimeter precision in every model, capturing even minor irregularities or early-stage defects. | Precision defect mapping |

| Thermal Integration | Infrared imaging overlays reveal heat signatures and internal stress zones, merging visible and thermal data into a single 3D view. | Early fault detection |

| Historical Tracking | Compare past inspections within the 3D twin to monitor defect evolution, repair quality, and long-term performance changes. | Continuous lifecycle insight |

| Cloud Collaboration | Teams can securely access, annotate, and share digital twins in real time, streamlining communication and workflow efficiency. | Faster maintenance coordination |

| Predictive Analytics | When integrated with Blade³.ai’s predictive models, digital twins can forecast future wear and optimize maintenance timelines. | Proactive maintenance planning |

| Compliance & Documentation | Each 3D twin acts as verifiable documentation for insurance, warranty, and regulatory audits, ensuring transparency and traceability. | Audit-ready inspection record |

| Sustainability | Reducing repeated site visits and manual inspections minimizes fuel use and emissions, supporting cleaner, more efficient wind operations. | Lower environmental footprint |

Blade³.ai’s digital twin technology turns complex inspection data into clear visual intelligence — empowering wind operators to make smarter, faster, and more sustainable decisions across every turbine.

U.S. States with Wind Turbines (2025 Estimates)

Wind power is active in more than 40 U.S. states, with Texas, Iowa, and Oklahoma leading the nation in installed capacity. These figures represent approximate onshore and offshore capacity in megawatts (MW) as of 2025.

| Rank | State | Installed Capacity (MW) |

|---|---|---|

| 1 | Texas | 42,000 |

| 2 | Iowa | 12,500 |

| 3 | Oklahoma | 11,000 |

| 4 | Kansas | 9,000 |

| 5 | Illinois | 8,500 |

| 6 | California | 6,500 |

| 7 | Minnesota | 5,000 |

| 8 | Colorado | 4,500 |

| 9 | North Dakota | 4,000 |

| 10 | Indiana | 3,000 |

| 11 | Nebraska | 3,500 |

| 12 | New Mexico | 3,800 |

| 13 | South Dakota | 3,300 |

| 14 | Michigan | 2,500 |

| 15 | Wyoming | 2,200 |

| 16 | Oregon | 2,100 |

| 17 | Washington | 2,000 |

| 18 | New York | 1,900 |

| 19 | Pennsylvania | 1,600 |

| 20 | Montana | 1,500 |

| 21 | Idaho | 1,200 |

| 22 | Maine | 1,100 |

| 23 | Arizona | 800 |

| 24 | West Virginia | 700 |

| 25 | Wisconsin | 650 |

| 26 | North Carolina | 550 |

| 27 | Missouri | 500 |

| 28 | Georgia | 250 |

| 29 | Virginia | 200 |

| 30 | Alaska | 100 |

Texas leads by a wide margin, followed by the Midwest corridor of Iowa, Oklahoma, and Kansas — representing the strongest regions for Blade³.ai’s autonomous inspection deployments across the United States.

Benefits of Offshore Turbine Inspection

Marine-Optimized Autonomy

Autonomous drones adapt to ocean winds, lighting, and vibration to ensure stable and safe data collection.

Impact: Reliable data capture even in harsh conditions.

AI Defect Detection

Blade³.ai’s computer vision models detect erosion, cracks, lightning strikes, and corrosion with near-perfect consistency.

Impact: 95%+ accuracy, fewer repeat missions.

Thermal Intelligence

Infrared sensors visualize internal heating and friction unseen by standard cameras.

Impact: Early fault detection and reduced mechanical failure risk.

Faster Inspection Cycles

AI processing and cloud sync cut inspection times by over 80%.

Impact: Less vessel time, lower operational costs.

Enhanced Safety

Eliminates rope access and manual climbs while minimizing offshore exposure.

Impact: Zero-risk inspection workflows.

Predictive Maintenance

AI forecasting identifies degradation trends before failure occurs.

Impact: Reduced downtime and longer turbine lifespan.

Cloud Reporting

Instant dashboards and downloadable reports simplify compliance and sharing.

Impact: Streamlined operations and audit-ready results.

Sustainability

Smarter flight planning and fewer vessel trips reduce emissions and energy use.

Impact: Greener, more efficient offshore maintenance.

About Blade³.ai

Blade³.ai is an AI-powered wind turbine inspection and analytics platform that helps operators optimize performance, reduce downtime, and extend the lifespan of renewable energy assets.

Through autonomous drones, infrared imaging, and predictive intelligence, Blade³.ai delivers real-time insights that make wind energy safer, smarter, and more sustainable.

Commitment to Sustainability

At Blade³.ai, we believe innovation should power a cleaner future.

Our mission is to help the renewable energy industry achieve net-zero emissions through intelligent automation, proactive maintenance, and smarter analytics.

Legal

© 2025 Blade³.ai. All rights reserved.